When it comes to controlling fluid flow in industrial, commercial, or residential applications, selecting the appropriate valve is crucial. Among the many types of valves available, gate valves and ball valves are two of the most common choices. Both serve the purpose of regulating fluid flow, but they differ significantly in terms of design, function, and application. Understanding the differences between gate valve vs ball valve will help you make an informed decision when selecting the right valve for your needs.

Valves play a critical role in ensuring efficient and safe fluid management across various industries. Whether you're working on plumbing systems, oil and gas pipelines, or water treatment plants, choosing the wrong valve type can lead to inefficiencies, leaks, or even catastrophic failures. This article delves into the key differences between gate valves and ball valves, providing insights into their unique characteristics and applications.

By the end of this guide, you'll have a comprehensive understanding of the strengths and limitations of each valve type. This knowledge will empower you to make the best choice for your specific project requirements, ensuring optimal performance and longevity.

Read also:Eric And Lara Trump Net Worth A Comprehensive Guide To Their Financial Empire

Table of Contents

- Introduction to Valves

- Gate Valve Overview

- Ball Valve Overview

- Key Differences Between Gate and Ball Valves

- Applications of Each Valve Type

- Factors to Consider When Choosing a Valve

- Cost Analysis

- Common Mistakes to Avoid

- Industry Standards and Certifications

- Conclusion and Final Recommendations

Introduction to Valves

Valves are mechanical devices used to control the flow of liquids, gases, or other substances within a pipeline or system. They serve multiple functions, including starting, stopping, regulating, and directing fluid flow. Valves are essential components in various industries, including oil and gas, water treatment, chemical processing, and HVAC systems.

There are numerous types of valves, each designed for specific applications. Among these, gate valves and ball valves stand out due to their versatility and widespread use. Both valve types have distinct advantages and disadvantages, making them suitable for different scenarios.

Before diving into the specifics of gate valve vs ball valve, it's important to understand the fundamental principles behind how valves operate and the factors that influence their performance. This foundational knowledge will help you appreciate the nuances of each valve type and make an informed decision.

Gate Valve Overview

Gate valves, also known as sluice valves, are one of the most common types of valves used in industrial applications. They are primarily designed for on/off service, meaning they are used to completely open or close fluid flow. Gate valves are not recommended for throttling or regulating flow due to their design limitations.

One of the defining features of gate valves is their wedge-shaped gate, which moves perpendicular to the flow of fluid. When the valve is fully open, the gate retracts completely, allowing unrestricted flow with minimal pressure drop. Conversely, when the valve is closed, the gate blocks the flow entirely.

Gate valves are available in various materials, including cast iron, stainless steel, and bronze, making them suitable for a wide range of applications. They are commonly used in water supply systems, oil pipelines, and industrial processes where full flow is required.

Read also:Bubba Strait Kids A Closer Look At The Next Generation Of Golfing Greats

Design Differences

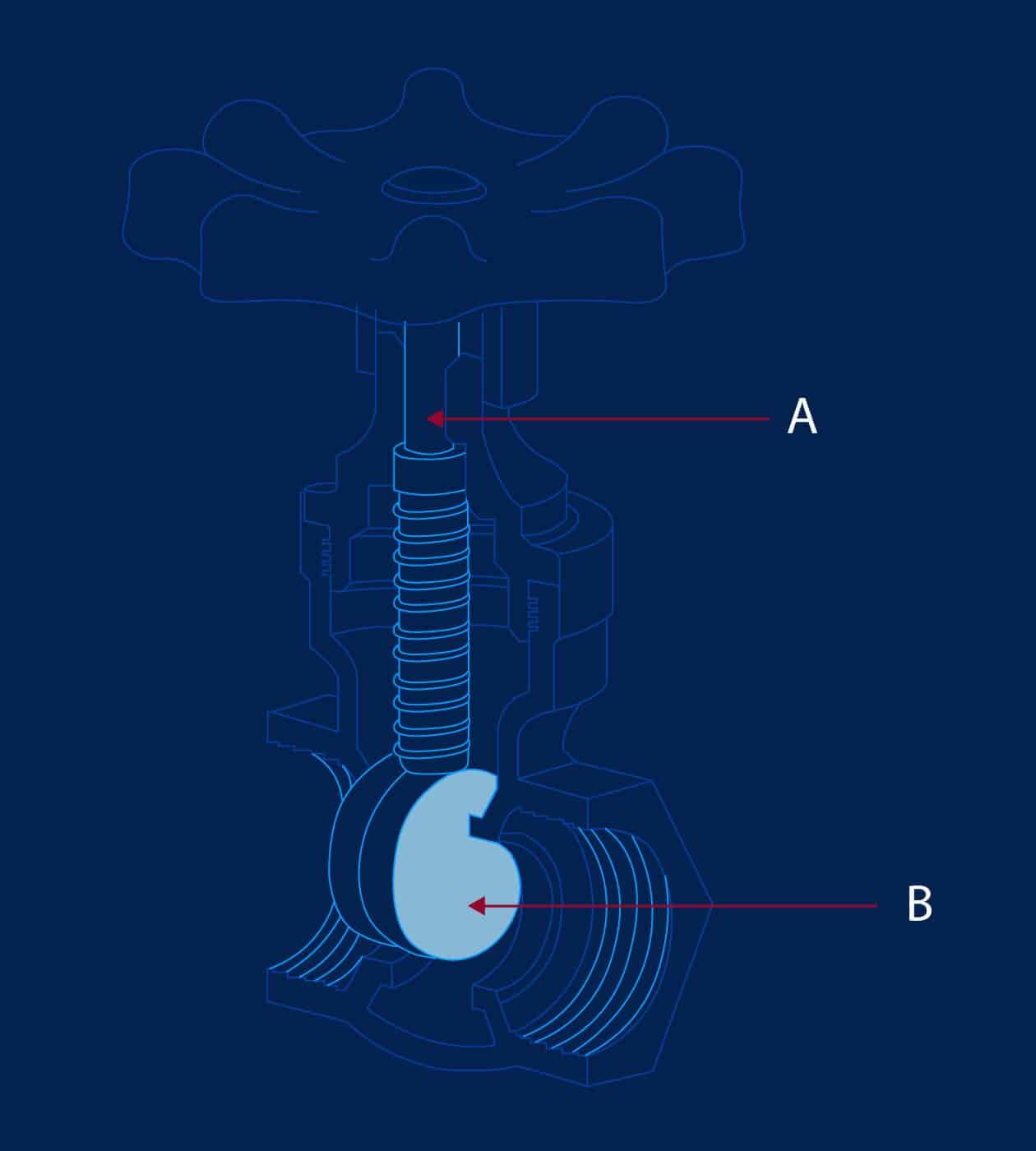

The design of a gate valve is characterized by its linear motion mechanism. The gate is attached to a stem, which is operated by a handwheel or actuator. As the stem is turned, the gate moves up or down, controlling the flow of fluid. Gate valves can be classified into two main types based on their design:

- Wedge Gate Valve: Features a solid or flexible wedge-shaped gate that provides a tight seal when closed.

- Parallel Slide Gate Valve: Uses two parallel disks that slide apart when the valve is opened, offering improved sealing capabilities in high-pressure applications.

The choice of design depends on the specific requirements of the application, such as pressure rating, temperature range, and fluid type.

Ball Valve Overview

Ball valves, on the other hand, are designed for rapid shutoff and are ideal for applications requiring frequent operation. They use a spherical disc with a hole in the center, which rotates to control the flow of fluid. When the hole is aligned with the pipeline, the valve is open, allowing fluid to pass through. When the ball is rotated 90 degrees, the hole is perpendicular to the pipeline, blocking the flow entirely.

Ball valves are known for their durability, reliability, and ease of operation. They are often used in applications where quick shutoff is critical, such as in firefighting systems, natural gas pipelines, and chemical processing plants. Ball valves are available in various materials, including brass, stainless steel, and PVC, making them suitable for a wide range of environments.

One of the key advantages of ball valves is their ability to maintain a tight seal even after years of use. This is due to the resilient seating material, which ensures minimal leakage over time.

Key Differences Between Gate and Ball Valves

While both gate valves and ball valves serve the same basic purpose, they differ significantly in terms of design, performance, and application. Understanding these differences is crucial when deciding which valve type to use for your project.

Design Differences

As mentioned earlier, gate valves use a linear motion mechanism, while ball valves rely on a quarter-turn rotation. This fundamental difference affects how each valve operates and the applications they are best suited for.

Gate valves are generally larger and heavier than ball valves, making them less suitable for space-constrained environments. Ball valves, on the other hand, are compact and lightweight, offering greater flexibility in installation.

Performance Comparison

In terms of performance, gate valves excel in applications requiring full flow with minimal pressure drop. They are ideal for large-diameter pipelines and systems where maximum flow capacity is essential. However, gate valves are not recommended for throttling due to their tendency to wear out under partial closure conditions.

Ball valves, on the other hand, are better suited for applications requiring frequent operation and rapid shutoff. They offer excellent sealing capabilities and can handle high-pressure and high-temperature environments. However, ball valves may experience higher pressure drops compared to gate valves, especially in larger sizes.

Maintenance Requirements

Maintenance is another critical factor to consider when choosing between gate valves and ball valves. Gate valves typically require more maintenance due to their complex design and tendency to accumulate debris. Regular cleaning and lubrication are necessary to ensure smooth operation.

Ball valves, in contrast, require minimal maintenance and are less prone to wear and tear. Their simple design and durable materials make them a low-maintenance option for many applications.

Applications of Each Valve Type

The choice between gate valve vs ball valve often depends on the specific application requirements. Here are some common applications for each valve type:

- Gate Valves: Water supply systems, oil pipelines, industrial processes, and large-diameter pipelines where full flow is required.

- Ball Valves: Firefighting systems, natural gas pipelines, chemical processing plants, and applications requiring rapid shutoff and frequent operation.

It's important to note that some applications may require a combination of both valve types to achieve optimal performance. For example, a water treatment plant may use gate valves for main pipelines and ball valves for auxiliary lines.

Factors to Consider When Choosing a Valve

When selecting a valve for your application, several factors should be taken into account:

- Pipeline Size: Larger pipelines may require gate valves for full flow, while smaller pipelines may benefit from the compact design of ball valves.

- Pressure and Temperature Ratings: Ensure the valve you choose can handle the pressure and temperature requirements of your application.

- Material Compatibility: Select a valve material that is compatible with the fluid being transported to prevent corrosion or other issues.

- Frequency of Operation: If the valve will be operated frequently, a ball valve may be a better choice due to its durability and ease of operation.

- Budget Constraints: Consider the initial cost of the valve as well as long-term maintenance costs when making your decision.

Cost Analysis

While ball valves are generally more expensive than gate valves due to their superior materials and manufacturing processes, they often provide better value over time. The low maintenance requirements and long service life of ball valves can result in significant cost savings in the long run.

Gate valves, on the other hand, may be more affordable upfront but can incur higher maintenance costs over time. Additionally, their tendency to wear out under partial closure conditions may lead to premature failure and replacement costs.

Common Mistakes to Avoid

When selecting and installing valves, there are several common mistakes to avoid:

- Using the Wrong Valve Type: Choosing the wrong valve type for your application can lead to inefficiencies, leaks, or even catastrophic failures.

- Ignoring Maintenance Requirements: Neglecting regular maintenance can shorten the lifespan of your valves and compromise system performance.

- Overlooking Material Compatibility: Using a valve material that is not compatible with the fluid being transported can result in corrosion, leaks, or other issues.

- Underestimating Pressure and Temperature Ratings: Failing to account for the pressure and temperature requirements of your application can lead to valve failure and safety hazards.

Industry Standards and Certifications

To ensure the quality and reliability of your valves, it's important to choose products that meet industry standards and certifications. Some of the key standards to look for include:

- ASME Standards: Covering the design, manufacture, and testing of valves, ensuring their safety and performance.

- API Standards: Providing guidelines for the use of valves in the oil and gas industry.

- ISO Standards: Offering international standards for valve design, materials, and testing procedures.

Choosing valves that comply with these standards ensures that they meet the highest quality and safety requirements.

Conclusion and Final Recommendations

In conclusion, understanding the differences between gate valve vs ball valve is essential for selecting the right valve for your application. While gate valves excel in applications requiring full flow and minimal pressure drop, ball valves are better suited for rapid shutoff and frequent operation. By considering factors such as pipeline size, pressure and temperature ratings, material compatibility, and maintenance requirements, you can make an informed decision that ensures optimal performance and longevity.

We invite you to share your thoughts and experiences in the comments section below. Have you encountered any challenges when selecting or installing valves? What factors did you consider in your decision-making process? Your feedback will help others in the community make better-informed choices.

For more insights into industrial equipment and best practices, explore our other articles on our website. Stay updated with the latest trends and technologies in the field by subscribing to our newsletter. Together, let's build safer, more efficient systems for a better future.